RIDC Mill 19 Phase A

Pittsburgh, PA

Jacob Kleindl

Construction

Dr. John Messner

Building Statistics

General Building Information

Project Team

General Building Overview

RIDC Mill 19 is the adaptive renovation of Mill 19 at the former LTV Steel fabrication site into a multi-tenant facility that will be anchored by Carnegie Mellon University’s Advanced Robotics for Manufacturing Institute. Phase A is a three story, approximately 102,000 gross square feet high bay building constructed under the existing steel shell of the old mill building (building within a building). The owner of this project is the Regional Industrial Development Corporation (RIDC), with MSR serving as the principal architect and Turner Construction acting as the general contractor.

Phase A is the first of three, three story office buildings to be constructed within the structural skeleton of an existing steel mill. The architect’s design decision to leave the steel members exposed was to pay tribute Pittsburgh’s history as one of the largest fabricators of steel during World War 1 and World War 2. Leaving the openings to see these three new office buildings through the old structural system blends modern architecture with the design features of the 20th century.

Architecture

RIDC Mill 19 A is the first of three, three story mixed use buildings that will be constructed within the structural skeleton of an existing centuries old steel mill. The architect chose to leave the steel members exposed to pay tribute to Pittsburgh’s history as one of the largest producers of steel during World War 1 and World War 2. Leaving openings to see the new buildings through the old structural system blends modern architecture with the design features of the 20th century.

Phase A itself is designed with high ceilings, and thick floors to accommodate the machinery incorporated in the Carnegie Mellon Robotics Division experiments as well as to provide acoustical insulation from equipment noise and vibration. The stairwell is located along the south side of the building, and acts as an atrium/vestibule 30 feet in height surrounded with glass panels. Openness, flow, and community were the goals of the architect when designing this space, so the large open stairwell coupled with a lot of glass panels positively contribute to the space. Offices and work stations outside of the research lab will contain no cubicles and only sliding glass doors for executive offices and conference rooms.

Pittsburgh has been synonymous with the colors black and gold as all three of the professional sports teams (Steelers, Pirates, and Penguins) don the same colors. This detail was incorporated in the design with the existing steel mill duty cranes scheduled to be painted Pittsburgh gold to contrast with the silver/black exterior still.

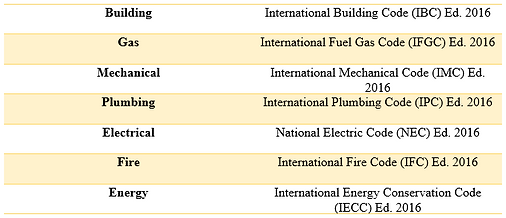

Building Codes

Zoning

Mill 19 is located within the city limits of Pittsburgh, so all building, demolition, occupancy permits, etc. must be filed and approved by the City of Pittsburgh Department of City Planning. Work specific to a type of permit may not begin until said permit is secured and posted on the project site. For example, duct work cannot be installed until the HVAC permit is approved by the city. For more information on the City Planning Office visit the website; http://pittsburghpa.gov/dcp/.

Building Enclosure

Building Enclosure

The exterior of the three-story research facility is encased with 3/16” vertical box rib metal paneling wherever double-paned windows and the glazed aluminum curtain wall sections are absent. MSR, the principal architect, delegated the curtain wall design because the manufacturer of the specialty product needed to perform checks and calculations to account for the expansion and contraction of the aluminum support system as well as all the bolted connections. Very little masonry was called for in this project with the only component being a non-load bearing concrete block knee wall with no scaffolding required around the perimeter of the building.

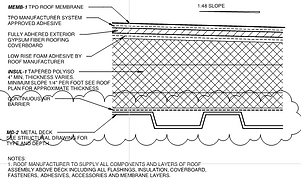

Roofing System

The outermost component of the roofing system is a TPO Roof Membrane with a slope of 1:48 paired with a fully adhered exterior gypsum fiber roofing coverboard. A 4” thick tapered PolyIso insulation is used in conjunction with metal decking to complete the roofing system. Multiple skylights with a slope of 1:12 are incorporated in the roof design.

Sustainability

Mill 19 Phase A’s basis of design is aiming to achieve a LEED Gold Certification. Included in the design’s efforts to accomplish this is a 2mw photovoltaic solar panel array that will be installed on the existing mill’s structural steel frame. The building will also utilize a water-source heat pump system for heating and cooling.

Construction

The design team decided to use a combination of insulated metal paneling and curtain wall to make up the exterior façade of the building. The sequence of the application of the building facade is as follows; cold-formed metal framing, sheathing, flashing, curtain wall clips, vertical mullions, glass plates, pressure bars, metal fins, metal panels, roofing. The curtain wall feature of Mill 19 is fastened to the cold-formed metal framing by way of galvanized aluminum curtain wall clips for support, followed by the installation of pressure bars to increase stability. The clips, pressure bars, plate glass as well as vertical mullions are installed using a mobile scissor lift capable of reaching 35 ft. high and supporting two laborers. Additional material can also be transported to location of the current work through the interior of the building by means of the temporary stares or freight elevator.

The Metl-Span CF Architectural insulated metal panel is outfitted with a lock and groove system and are to be installed vertically. Several installation methods are listed for the product including graphics for a wet-seal system, and dry-seal system installation, but the method used in this project is the face fastened solution pictured to the right. As seen in the diagram the screw creates an opening in the insulation on the interior side of the panel, which then is rectified by the application of a relatively new type of flashing called fast flash developed by Georgia Pacific. Due to the high cost of the panel as well as the sequence in which the the exterior façade is installed, the metal panel is placed last in an effort to ensure the exterior finsh is not compromised.

The crews for both the curtain wall and metal panel installation consisted of one foreman and seven laborers along with two mobile scissor lifts with the capabilities detailed above. These crews were divided in half so that one crew from each trade works on both the east and west sides simultaneously. Curtain wall sections were prefabricated off-site then stood up in their assigned sections of the building façade, rather than being stick-built. The teams in charge of metal paneling followed the curtain wall crews on a south to north plane until the façade installation is complete. An identical process was used for the north and south sides of the building, but the crews worked from east to west.

The roofing system is a fully adhered built up TPO roof with a vapor barrier and protection boards. This chosen design is applied in the following order; protection board on roof deck, peel and stick vapor barrier on protection board, rigid installation base layer and tapered insulation, then the TPO roof membrane. The installation process starts on the south end moving north and working out from the middle of the roof to the parapet walls. This method allows the construction team to start in the middle of the roof prior to the parapet walls being constructed and buttoned up.

Project Delivery Method & Contract

Mill 19 implemented a construction manager agent project delivery system with a Cost Plus Negotiated GMP contract worth $22 million between RIDC and The Turner Construction Company. MSR Architects was selected to do the building design and sought out the consultants and engineers they thought would make up the best team to deliver the owner’s vision for the project. The selection process for a contractor involved the owner engaging a construction manager partner early to assist with preconstruction services (estimating, scheduling, etc.). Turner’s track record and procurement team were the two main reasons they were chosen as the general contractor has completed many difficult projects in the area highlighted by the Pittsburgh Convention Center located in downtown Pittsburgh.

Various types of insurances and bonds were included in the GMP proposal such as subcontractor default insurance, subcontractor CCIP insurance, Turner CCIP insurance, and a Turner Surety Bond. A design-bid-build with a GMP is an appropriate choice for this project as the pairing of an owner who is a non-profit developer and a tenant with a grant that is on a time constraint cannot assume any additional costs if issues arise, so this burden would fall on Turner.

Primary Building Systems

Electrical/Lighting System

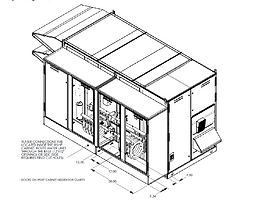

The electrical system that is to be installed includes a new 2,500A, 480/277V switchboard that provides power distribution to multiple tenants along with a 1,600A, 480/277V switchboard dedicated to the new central utility plant. This new electrical system is equipped with full metering and complete integration with the Building Management System (BMS). There are provisions in place for a new 400 kW emergency generator which would provide N+1 redundancy that is expected to be implemented by the tenant.

Structural System & Site Preparation

The structural steel system utilized for the project is a standard beam and column layout with composite metal decking. Cast in place concrete for the project included horizontal slab on deck pours for levels two and three and were done by a concrete truck with an adjustable hose attachment. Precast concrete was limited to the treads and risers for the ornamental staircases on the west side of the building. A 50 ton crawler crane was employed to erect the structural steel as well as lower the precast treads and risers into place.

Selective demolition was performed and included mainly the removal of metal roof and wall panels from the existing mill. There was an asbestos hazard when removing the roof panels, but it was handled by a third party contracted by the owner with oversight provided by Turner. Excavation support was implemented but was limited to trench boxes as the size of the site allowed for step backs and slopes to be used for most deep digs. Pits, wells, and sump pumps were all used as part of the site de-watering system, which pumped water through a filtration system to an existing retention pond.

Mechanical System

The mechanical system includes four (4) rooftop air handling units that provide both heating and cooling. HVAC distribution includes variable volume terminal units (VAV) that dispense air throughout the building. Cooling is provided via one (1) cooling tower and two (2) condenser water heat exchangers. Heat distribution is supplied by two (2) electric hot water boilers.

Supporting Engineering Systems

Transportation

There are two elevators located along the West exterior wall of Mill 19. The elevators are located along one of the many curtain wall sections of the building, so the walls of the elevator are glass as well with the people using them being able to look over the scenic river as well as the rest of the Mill 19 campus. In addition to the elevators there is one high-ceiling, vestibule interior stairwell encased in curtain wall along the West side of the building, and one exterior steel staircase that only provides access to the ground and second floor.

Telecommunications

The primary telecommunications room is located in the Southwest corner of the first floor. All future employees who work in this building will have security ID badges because nearly all doors that are not access to public areas will have card readers. Security cameras are also incorporated into the building design and the intertwined network will work in unison to provide coverage of the entire building. These will operate within a closed system and be fed to monitors located in the primary telecommunications room mentioned above.

Fire Protection

The type of fire protection utilized by Mill 19 is wet system anchored by a pressure pump. Automatic sprinklers are strategically integrated within the building design to meet code as well as disperse water whenever the alarm is tripped or the sprinkler cap receives enough heat for the interior sensor to activate the system. The pump, located in the shared utility building, uses pressure to push the water throughout the suppression system.